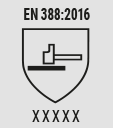

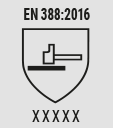

- EN 388:2016, Mechanical risks, 3121X

- Polyamide fine-knit gloves – feel like a second skin

- Palm with extra thin polyurethane coating, Therefore an ideal fit

- Application areas: Warehousing, quality control and product protection and for work that requires better grip security and a perfect fit

- Length: approx. 25 cm

Important: The assessment is not a legally binding statement about the actual application suitability. For thisplease refer to the respective EN standards with the test code of the various gloves here in the text of the details screen.

Mechanical risks

Protection gloves of this standard need to protect against physical and mechanical loads such as wear, cuts, puncturing, tearing or felling cuts. These loads can occur when working with metal or wood or any other tasks where hands need to be protected against mechanical injury. Also, they must comply with the regulations relating to electrical conductivity of protection gloves.

Protection gloves for mechanical risks must satisfy at least one of the test criteria listed in the table.

Testing Criteria:

Abrasion Resistance: 0-4

Cut Resistance: 0-5

Tear Resistance: 0-4

Puncture Resistance: 0-4

EN-ISO cut resistance: A-F

EN impact protection: yes/no

The higher the number (shown with an X below the icon in the example), the better the test result.

Thanks to the use of various coats, the hands are well protected in coated textile gloves whatever the task. Depending on the gloves chosen, the wear-resistant gloves offer excellent dexterity and are resistant to oil, grease and wet. Non-slip grip under light to heavy loads.

- Flexible and elastic

- Breathable

- Good grip in oil

- For precision work

Polyurethane

Thanks to the polyurethane coating – the gloves are liquid-repellent and highly durable with an excellent grip. Gloves with a polyurethane coating are used wherever high mechanical loads and sharp materials are expected.

Price

Available colours

Available sizes

Glove application recommendation

Glove total length

Material / coating

Protection standard

Extras

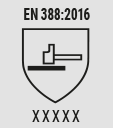

Mechanical risks

Protection gloves of this standard need to protect against physical and mechanical loads such as wear, cuts, puncturing, tearing or felling cuts. These loads can occur when working with metal or wood or any other tasks where hands need to be protected against mechanical injury. Also, they must comply with the regulations relating to electrical conductivity of protection gloves.

Protection gloves for mechanical risks must satisfy at least one of the test criteria listed in the table.

Testing Criteria:

Abrasion Resistance: 0-4

Cut Resistance: 0-5

Tear Resistance: 0-4

Puncture Resistance: 0-4

EN-ISO cut resistance: A-F

EN impact protection: yes/no

The higher the number (shown with an X below the icon in the example), the better the test result.

Thanks to the use of various coats, the hands are well protected in coated textile gloves whatever the task. Depending on the gloves chosen, the wear-resistant gloves offer excellent dexterity and are resistant to oil, grease and wet. Non-slip grip under light to heavy loads.

- Flexible and elastic

- Breathable

- Good grip in oil

- For precision work

Polyurethane

Thanks to the polyurethane coating – the gloves are liquid-repellent and highly durable with an excellent grip. Gloves with a polyurethane coating are used wherever high mechanical loads and sharp materials are expected.

Mechanical risks

Protection gloves of this standard need to protect against physical and mechanical loads such as wear, cuts, puncturing, tearing or felling cuts. These loads can occur when working with metal or wood or any other tasks where hands need to be protected against mechanical injury. Also, they must comply with the regulations relating to electrical conductivity of protection gloves.

Protection gloves for mechanical risks must satisfy at least one of the test criteria listed in the table.

Testing Criteria:

Abrasion Resistance: 0-4

Cut Resistance: 0-5

Tear Resistance: 0-4

Puncture Resistance: 0-4

EN-ISO cut resistance: A-F

EN impact protection: yes/no

The higher the number (shown with an X below the icon in the example), the better the test result.

Thanks to the use of various coats, the hands are well protected in coated textile gloves whatever the task. Depending on the gloves chosen, the wear-resistant gloves offer excellent dexterity and are resistant to oil, grease and wet. Non-slip grip under light to heavy loads.

- Flexible and elastic

- Breathable

- Good grip in oil

- For precision work

Polyurethane

Thanks to the polyurethane coating – the gloves are liquid-repellent and highly durable with an excellent grip. Gloves with a polyurethane coating are used wherever high mechanical loads and sharp materials are expected.